News

Efficiently Solving the Challenges of Microcrystalline Glass Hot Bending Processing

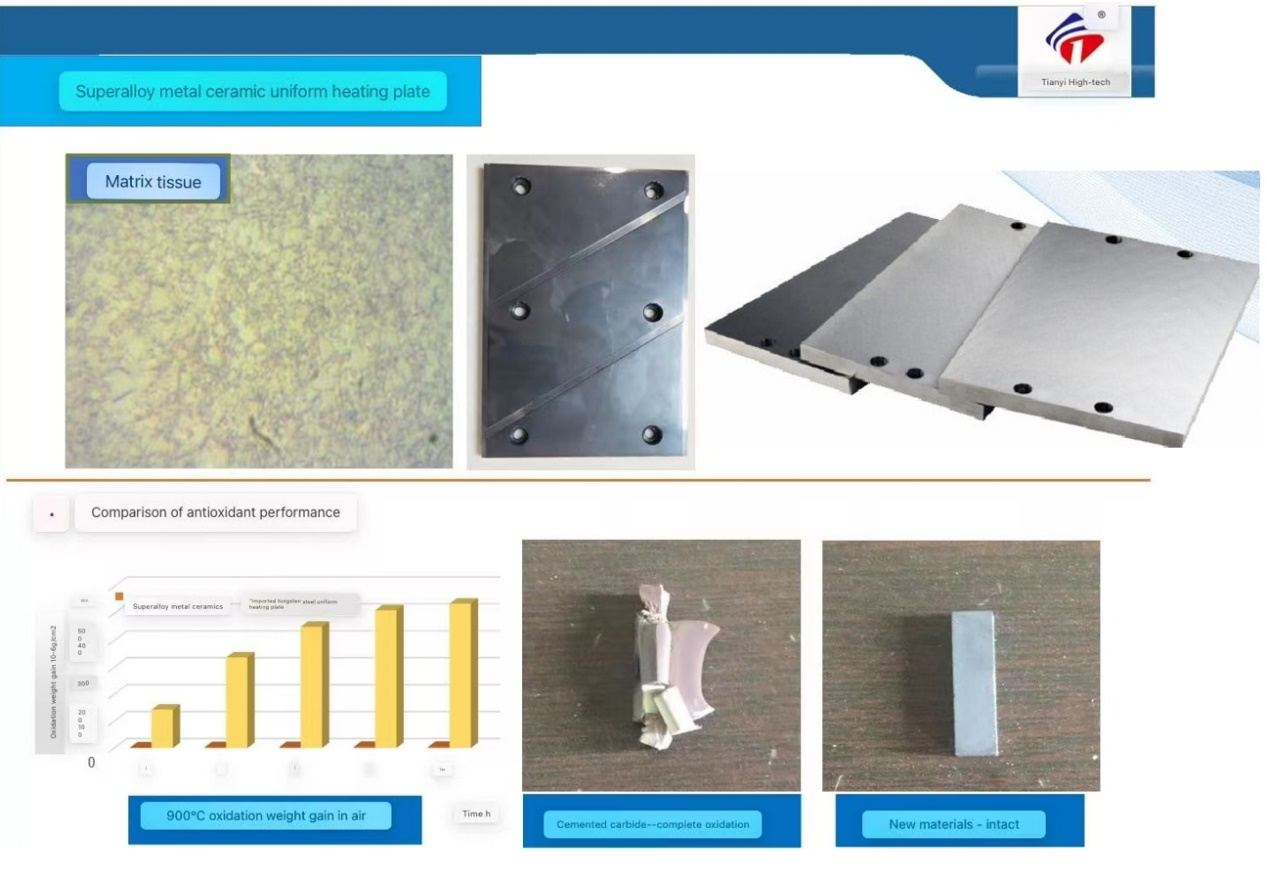

To meet the high-temperature processing demands of microcrystalline glass during hot bending, and in contrast to the poor oxidizing resistance and short service life of traditional tungsten steel materials, Tianyi Company has launched a superalloy metal ceramic plate specifically developed for high-temperature forming operations.

This product has been optimized for high-temperature hot bending forming equipment such as 3D glass bending machines, aspherical precision press machines, and automotive freeform (HUD) glass precision press machines, and has the following significant advantages:

1. Higher hardness

2. Excellent high-temperature oxidation resistance

3. Uniform heat conduction with minimal temperature deviation

4. Minimal deformation

The superalloy metal ceramic plate, through optimized temperature and pressure control, has successfully solved the processing challenges of microcrystalline glass during high-temperature hot bending. It provides strong support for the precision molding of microcrystalline glass, helping enterprises to stand out in fierce market competition.

Related product categories

- carbide roller rings for finishing stands

- carbide roller rings for roll rings

- carbide roll rings with excellent thermal conductivity for steel mills

- cost-effective roll rings for tube mills

- carbide rolls for mance rolls

- carbide rolls for plate mills

- cost-effective roll rings Russia

- how to choose roll rings United States

- china cemented carbide lathe tools

- cnc end mill kit

- end mill flat

- end mill bits for steel

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de