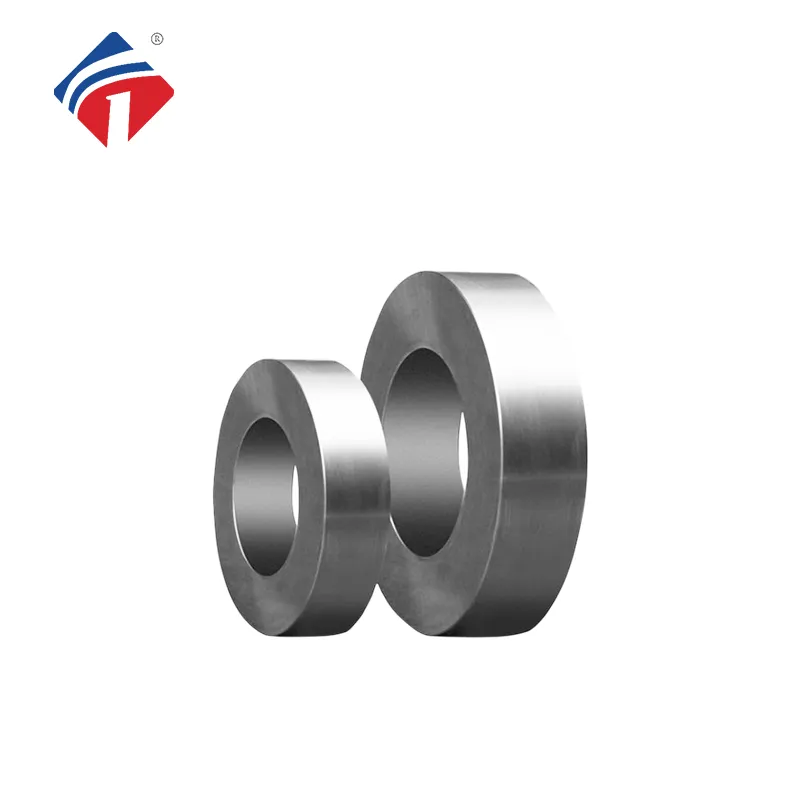

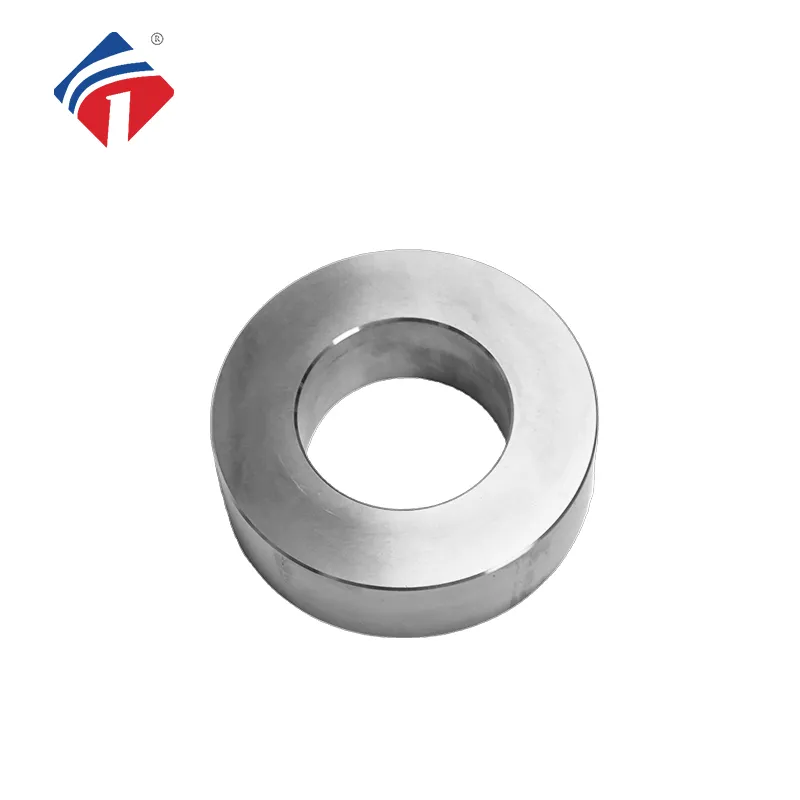

1) The specification of the cemented carbide roller

Polishing Roller

Product Information

* Material: WC, Metallic binder (Cobalt, Nickel, etc.)

* Roller Style: Light roller /Grooving roller/Threaded roller.

* Application: Pre-finishing & Finishing Rolling In Rolling Mill

* Types of Rolling: Hot Rolling(High-Temperature),Cold Rolling(Room temperature)

* Surface: Polishing

* Advantage: exceptional hardness, high wear resistance, high resistance, and durability

* Certification: ISO Certificate

* Other Services: OEM/ODM

Description

Technical Parameter

|

Rang of O.D. |

Rang of I.D. |

Rang of height |

|

145-330 |

87-260 |

45-130 |

2) The tolerances allowable for the outer diameter, inner diameter, and height of roll rings

|

Precision Index |

1 |

2 |

3 |

4 |

Special requirements |

|

O.D. (±) |

0.02 |

0.05 |

0.10 |

0.15 |

|

|

0.D. (±) |

IT 5 |

IT6 |

IT7 |

IT8 |

|

|

Height(-) |

0.03 |

0.1 |

0.20 |

0.5 |

3) The allowable deviation of carbide roll rings

a. Radial runout of groove: ≤0.013mm

b. Radial runout of geriphery: ≤0.013mm

c. End face runout: ≤0.02mm

d. End face planeness: ≤0.01mm

e. End face parallelism: ≤0.01mm

f. Inner hole cylindericity: ≤0.01m

4) Roughness of carbide rolls

Inner hole roughness: 0.4μm

Periphery roughness: 0.4μm

End face roughness: 0.4μm

Note:

The allowable deviation in external diameter, diameter, and height is to be determined based on the customers' needs.

We can customize your size & materials according to the drawings provided by customers.

If you'd like to know more details, please find the relevant documents through the following links or download them from the homepage.

① The table of specifications of the finished carbide roll blanks

② Recommended applications of grades for carbide roll rings

③ Table of grades and properties of carbide roll rings and related data

④ Operational requirements of cemented carbide roll rings

INQUIRY

Related product categories

- carbide rolls for steel mills

- import carbide roll rings from China for roll rings

- carbide roller rings for bar mills

- buy carbide roll rings for bar mills

- cemented carbide roll ring manufacturers for rolling mills

- long-life roller rings for mance roller rings

- high-quality carbide roll rings Saudi Arabia

- tungsten carbide roll ring suppliers Saudi Arabia

- roller rings Saudi Arabia

- china cnc end mill

- cnc cutting tool

- end mill cnc bits

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de